Ultrasonic deburring machines - ultraTEC innovation

The solution to your deburring problem.

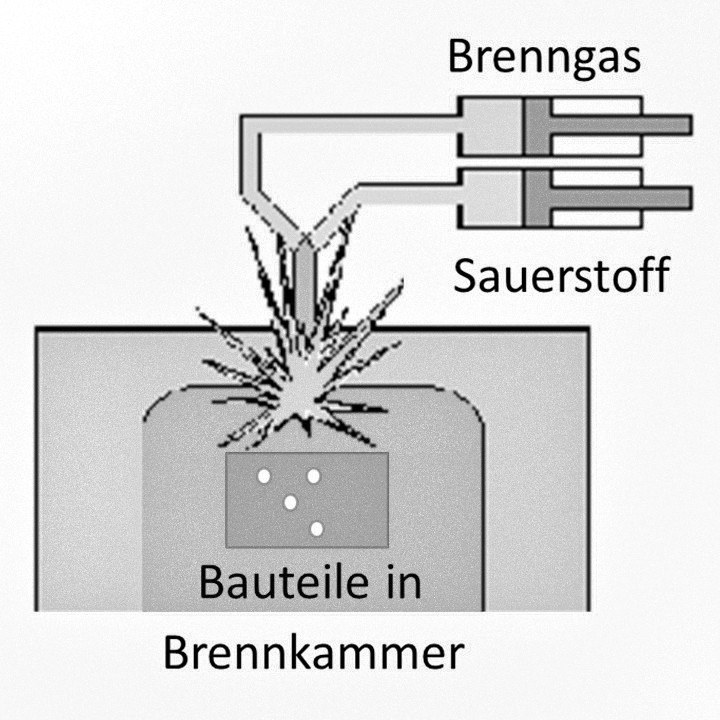

Our flexible and resource-saving ultrasonic deburring systems are the perfect alternative to thermal deburring and high-pressure water jet deburring!

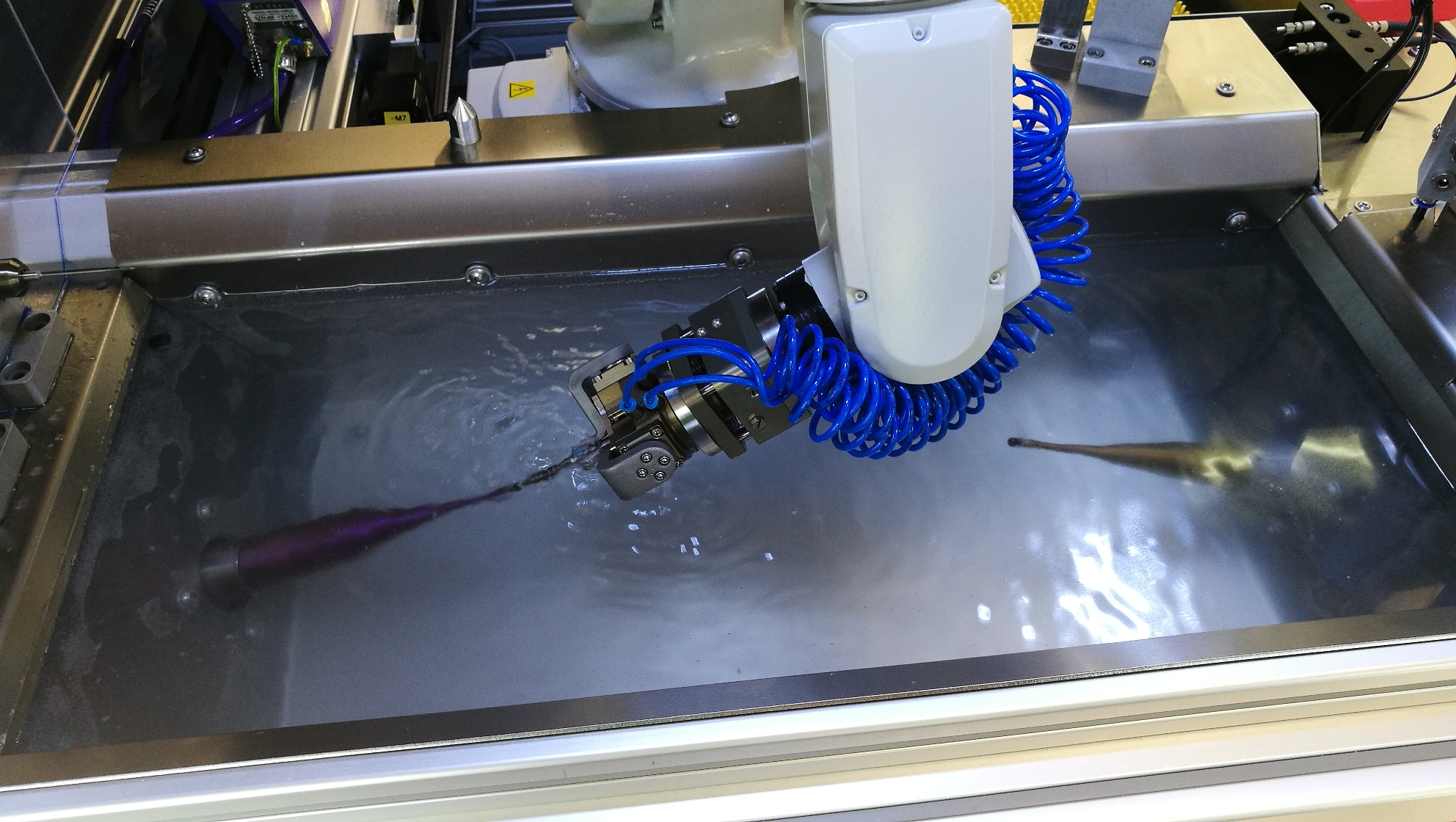

How it works:

In a process water basin, an ultrasonic horn oscillates and generates sound waves as well as cavitation. These remove burrs reliably and with sharp edges. This process can also be used to remove internal and hidden burrs.

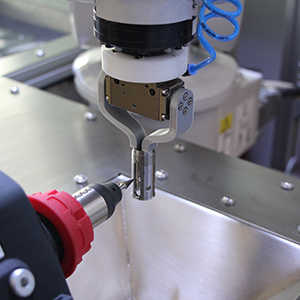

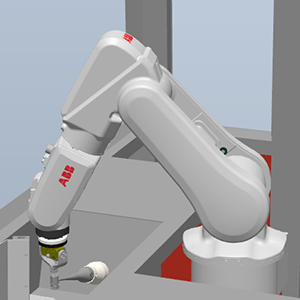

Never imagined flexibility:

With the option of a motor spindle in the robot compensation joint the possibilities of deburring with the machine multiply. Sharp edges and different sized chamfers of one component, not a problem for our machines. We would gladly do a sample deburring for you.

Ultrasonic deburring in 100 seconds

Advantages over thermal deburring:

- No deformations on the component.

- No discolorations on the surface.

- No changes to the oxide layer.

- Resource-saving and environmentally friendly.

- Minimize hazards to employees.

Advantages over high pressure water jet deburring:

- Only 3-5% of the energy requirement.

- No expensive fixture costs.

- Eligible as a replacement investment.

- Different drilling diameters without setup times.

- No injuries from the high pressure.

No restrictions in the construction geometry!

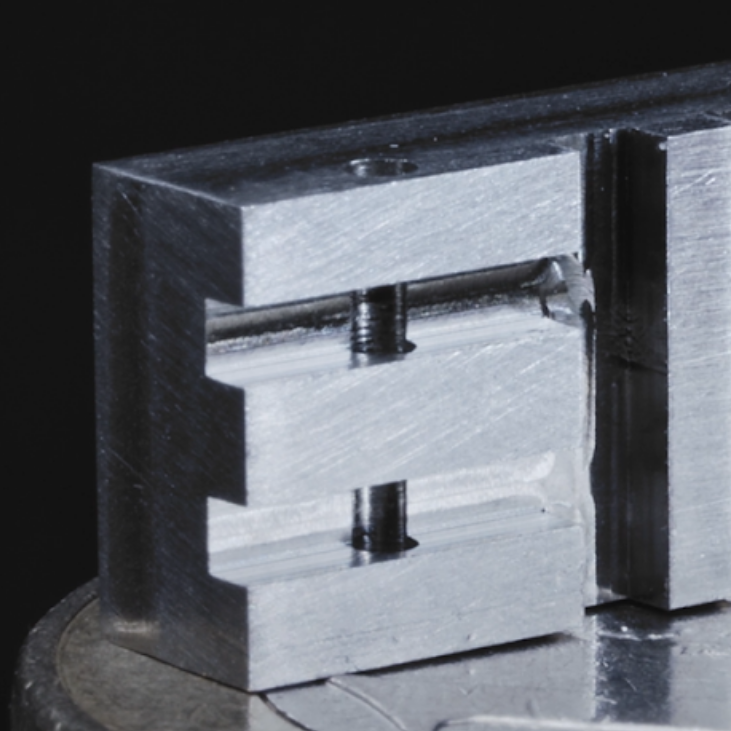

Cross bores

Expensive and inflexible fixtures, as required by classic processes, are no longer necessary. Cross bores starting at 0.2mm can be deburred reliably.

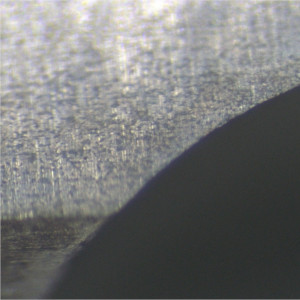

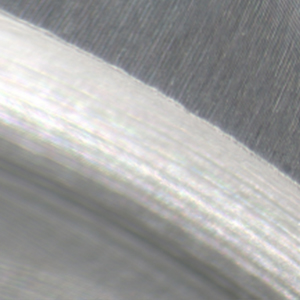

Grinded or honed components

Ultrasonic can even be used to deburr grinded or honed components. The machined edges remain sharp.

Learn more

Sharp-edged or with a chamfer

With our optional motor or compressed air spindle, you can apply additional chamfers with the same machine. Thus, sharp-edged and burr-free chamfers can be achieved with one machine.

Learn more

Concealed edges

Indirect ultrasonic radiation and the generation of Rayleigh waves (surface earthquake waves) make it possible to deburr even internal edges and the smallest of passages. The size does not matter.

Sensitive surfaces

Even highly sensitive surfaces can be deburred without damage. No surface discoloration and deformation of the component and very low abrasion rates.

Lot sizes 100 until 1 million

By using our programming systems, the machines can flexibly deburr smaller lot sizes starting at 100 pieces economically. Large quantities up to approx. 1 million are also possible.

Materials difficult to deburr

Ultrasonic deburring is almost independent of the material. A wide variety of metals and plastics can be deburred.

Learn more

Validatable process

Do you work in medical technology or in the automotive environment and need a validatable process? Ultrasonic deburring is particularly suitable for this.

Learn more

Resource-saving and environmentally friendly

Our A-series requires only 4 kW of power and the consumption per year is between 8,000 and 12,000 kWh per year. This is 3-6% of the energy of classic processes..

Learn more

Micro parts

Components as small as 1x1x1mm can be deburred with our machines.

Watch video